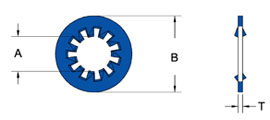

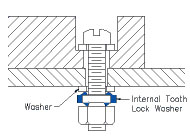

Internal Tooth Lock Washer, Internal Locked Tooth Washer, Star Washer

Internal tooth lock washer prevents the nut from loosening on screw.

Definition:

An internal tooth lock washer has teeth that extend radially inward to bite into the bearing surface. The internal tooth lock washer is designed to prevent a nut or bolt head from loosening with the strut action set up by the teeth. The teeth, also, absorb shock and vibration. The teeth abrade the grounding surface in electrical grounding applications to improve the electrical connection.

Internal Tooth Lock Washers are available in the following materials and finishes:

- Spring Steel: Baking, Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel 410: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Passivate, Pickling, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

Internal Tooth Lock Washer: 5855

Metric Internal Tooth Lock Washer: 5854

VIEW PRODUCTS

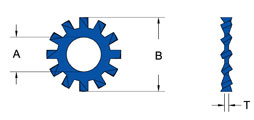

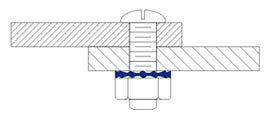

External Tooth Lock Washer, External Locked Tooth Washer

Definition:

An external tooth lock washer has teeth that extend radially outward to bite into the bearing surface. Like internal tooth lock washers, they are designed to prevent a nut or bolt head from loosening with the strut action of the teeth. They work best with larger screw or bolt heads. External tooth lock washers provide maximum torsional resistance.

External Tooth Lock Washers are available in the following materials and finishes:

- Spring Steel: Baking, Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel 410: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Passivate, Pickling, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

External Tooth Lock Washer: 5857

Metric External Tooth Lock Washer: 5856

VIEW PRODUCTS

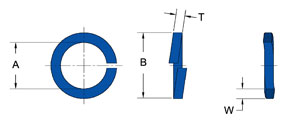

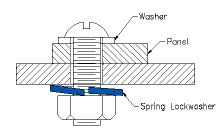

Helical Lock Washer, Helical Spring Lock washer, Split Lock Washer

Prevents the nut from loosening on screw.

Definition:

Helical Spring Lock Washers are the most commonly used to prevent assembly components from loosening. They apply greater bolt tension per unit of applied torque and provide protection against loosening resulting from vibration and corrosion. The split in the helical lock washer provides the resistance to the rotation of the screw when the tension in the assembly is reduced.

Helical Lock Washers are available in the following materials and finishes:

- Spring Steel: Baking, Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel 316: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Passivate, Pickling, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

Helical Lock Washer: 5850

VIEW PRODUCTS

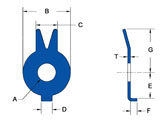

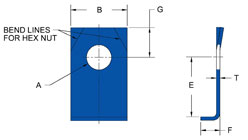

Tab Lock Washers

The tabs of the Tab Lock Washer hold the nut in place in relation to the chassis.

Definition:

Tab lock washers are designed to prevent both the washer and the nut from rotating in an assembly. The tabs lock over the edge of the assembly base or in a predrilled hole. The ears are bent up by the user to lock the nut in place.

Tab Lock Washers are available in the following materials and finishes:

- Cold Rolled Steel (Steel): Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel 301-304: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Passivate, Pickling, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

Tab Lock Washer: 5748

Tab Lock Washer: 5749

Tab Lock Washer: 5745 - Style 1

Tab Lock Washer: 5745 - Style 2

VIEW PRODUCTS