Concave Expansion Plugs, Dome Expansion Plugs, Welch Style Expansion Plugs, Core Plugs

Definition:

Concave expansion plugs are inexpensive, efficient, and are a permanent method of sealing manufactured holes in castings or other processes. These are good for use in limited space (depth) holes, but do require a counterbored hole to locate properly.

Alternate Definition:

Concave expansion plugs can be steel stamped and used as a nameplate for identification.

Concave (Welch Style) Expansion Plugs are available in the following materials and finishes:

- Aluminum: Anodize, Cadmium types I & II, Degreasing, Bright Nickel, Pickling, Silver, Bright Tin, Hot Tin Dip, Zinc types I & II

- Brass: Black Oxide, Cadmium types I & II, Degreasing, Bright Nickel, Pickling, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Cold Rolled Steel (Steel): Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

- Stainless Steel 301-304: Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

Concave Expansion Plug: 5790

VIEW PRODUCTS

Tapered Cup Expansion Plugs, Cupped Plugs

Definition:

Tapered cup expansion plugs, similar dome expansion plugs, are inexpensive, efficient and are a permanent method of sealing manufactured holes in castings or other processes. These do not need a counterbore like the core plug. It can withstand higher pressure than the concave expansion plug.

Tapered Cup Expansion Plugs are available in the following materials and finishes:

- Cold Rolled Steel (Steel): Black Oxide, Cadmium types I & II, Chrome, Degreasing, Bright Nickel, Pickling, Phosphate, Silver, Bright Tin, Hot Tin Dip, and Zinc types I & II

Concave Expansion Plug: 5791

VIEW PRODUCTS

Expansion Plug Installation

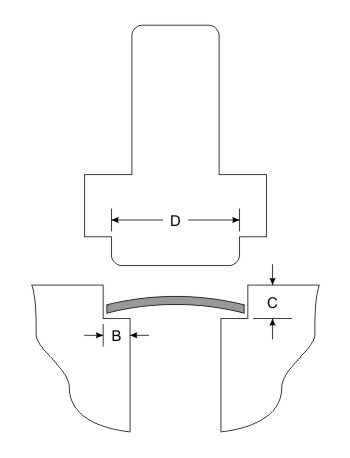

Type 5790 Concave Style Expansion Plugs

A. Hole Preparation

- Recommended counterbore diameter = max. plug diameter + 0.002.

- Counterbore should have a finish of 100 microinches or smoother.

- The counterbore must be clean and smooth with a sharp, square corner. A fillet may prevent the plug from sealing properly.

- Counterbore diameter should be round within 0.002 T.I.R.

- Counterbore depth (C in illustration) should be 1-1/2 times plug metal thickness minimum.

- Counterbore "ledge" (B in illustraion) should be approximately 1/10 of plug diameter or 1/4", whichever is less.

B. Installation

- Plug should be installed with a tool similar to that shown in illustration. Tool diameter D = 0.95 x counterbore diameter.

- The tool should be designed to bottom out when the plug is flattened 30% or more of its formed height but never flattened completely. The amount of flattening must be established by the user depending on the tightness required of the seal consistent with other factors of the user's design.

- A gasket type sealant may be used for severe applications.

- Plugs should be driven square to the hole. The shoulder on the driving tool should bottom out on the part the plug is being driven into. This will control alignment and proper depth.

C. Caution

- Barrel plating may nick the edges of the larger plugs and impair their sealing qualities.

- This data has been obtained from various sources, including "in-house" testing. While we believe it to be valid, we do not assume any responsibility for its use due to circumstances which may vary widely between users.

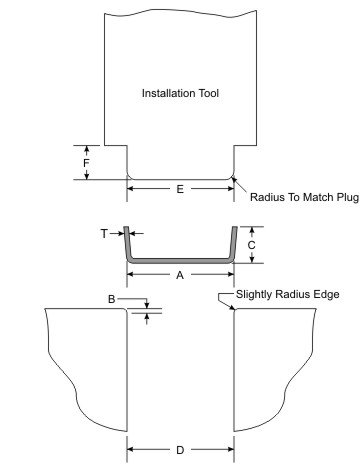

Type 5791 Tapered Cup Style Expansion Plugs

A. Hole Preparation

- Recommended hole diameter D = max. A + 0.003.

- Hole should have a finish of 100 microinches or smoother.

- Hole should be round within 0.002 T.I.R.

- E = min. A - (2T + 0.025)

- F = C + B + 0.035

B. Installation

- Plugs should be driven from the inside bottom, not from the rim of the cup, per illustration.

- If a gasket sealant is not used, lubricate the plug and hole with oil or grease before inserting.

- Plugs should be driven square with the hole. The shoulder on the driving tool should be bottomed on the part the plug is being driven into. This will control alignment and proper depth insertion.

- Plugs must not touch the bottom of a counterbored hole this may cause leaking.

C. Caution

- Barrel plating may nick the sides of these cups and destroy their sealing surface.

- This data has been obtained from various sources, including "in-house" testing. While we believe it to be valid, we do not assume any responsibility for its use due to circumstances which may vary widely between users.