Precision Stamping

Seastrom has the ability to produce a wide variety of parts to your specifications from both compound and progressive

tooling ranging from simple to complex, all fully supported by our in-house tool and die department. Parts can be made

from coil or strip material up to 6” wide and in thickness ranging from .001 to .134 in a variety of metallic or non-metallic materials.

VIEW DETAILS

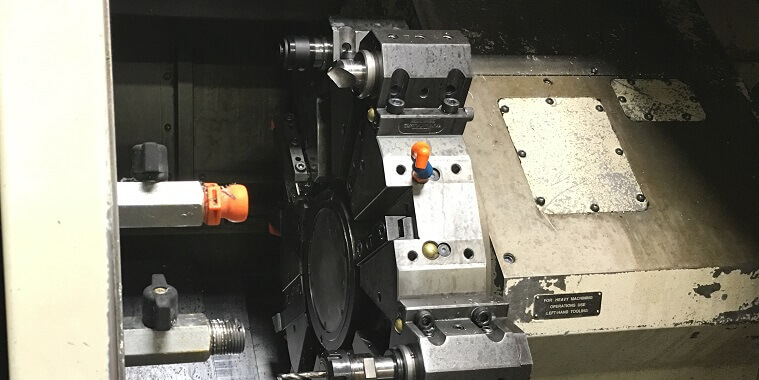

CNC Machining

Seastrom’s CNC milling and turning centers are capable of manufacturing intricate parts that require extreme accuracy and

consistency. This computer aided process produces parts from original CAD designs in most machinable metals and non-metals.

Seastrom’s CNC mills have a surface area capacity of 40”x64” and our CNC lathes can machine parts up to 10” in diameter.

VIEW DETAILS

Swiss CNC Automatic Lathe

Our Swiss CNC Automatic Lathe is ideal for highly precise and complex turned parts.

Seastrom’s Swiss CNC include 7-axis capabilities with a 10,000 rpm spindle, and an additional X2 axis which makes front

and back part machining possible simultaneously.

VIEW DETAILS

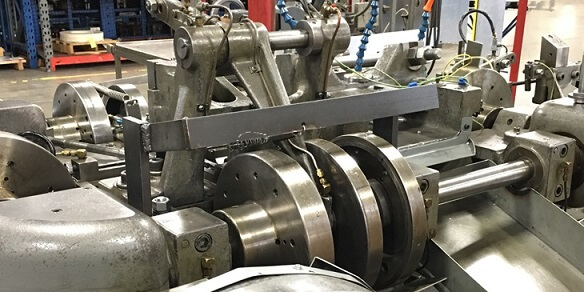

Multi Spindle Screw Machining

Utilizing Davenport Multi-Spindle Screw Machines, Seastrom is able to produce complex turned parts up to 7/8” diameter.

These machines are capable of completing multi-operation parts, making the process extremely efficient and eliminating the need

for many costly secondary operations.

VIEW DETAILS

Four-Slide

A unique and cost effective process that combines forming and stamping all in one machine. It is ideal for multi-bend and

wrapped parts such as electrical contacts, and spring or component clips. All four-slide tooling is created in-house by Seastrom’s

tool and die department and can be incorporated with other features such as in die tapping.

VIEW DETAILS

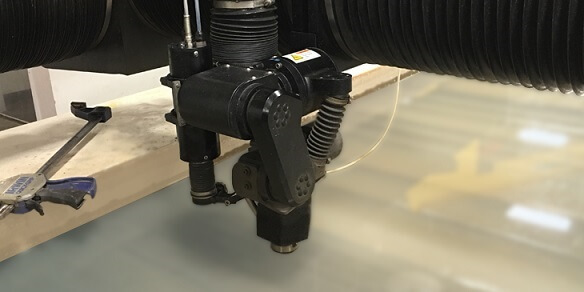

Water Jet

This technology uses a very high pressure stream of water to achieve both accurate and sophisticated part fabrication. One optimal benefit

is that parts can be produced rapidly without additional cost of tooling. Seastrom’s water jet machine has a total bed capacity of 4’x8’ and

has the ability to cut most metallic and non-metallic materials up to 8 1/2” thick.

VIEW DETAILS

Laser Part Marking

Many government and industrial regulations require clearly legible and permanently marked parts. Seastrom’s laser engraving process simulates

CNC engraving at a fraction of the time and cost. Metallic and non-metallic materials can be laser engraved with serial or model numbers, or

brand your product with your logo.

VIEW DETAILS

Special Packaging

In addition to bulk packaging, Seastrom can package products individually or in multiples utilizing high speed packaging equipment.

Special packaging, static-resistant packaging, custom labeling, bar coding and kitting services are available as well.

VIEW DETAILS

Engineering

Seastrom works side by side with its customers to assist in developing parts that will increase value and lower costs. With so many

capabilities, you can trust the experience and many years of industry knowledge that Seastrom’s engineers employ to develop the most cost

effective and efficient process to produce your part.

VIEW DETAILS